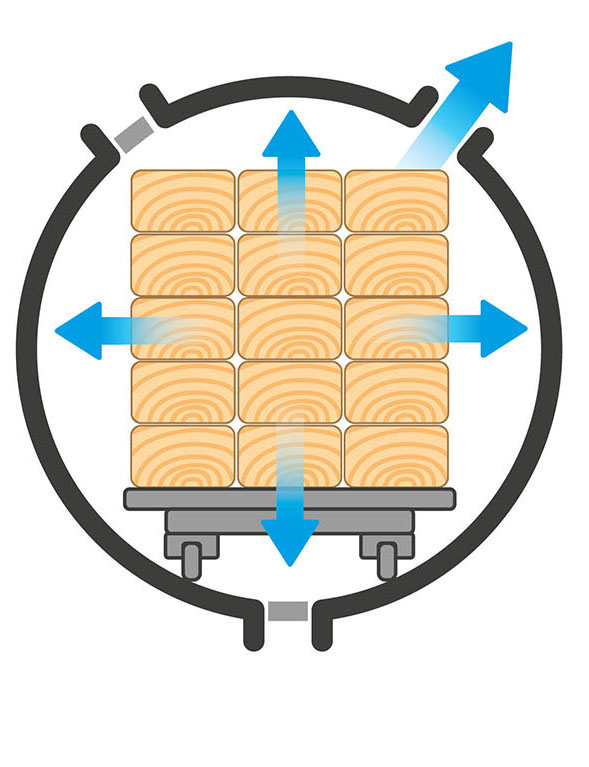

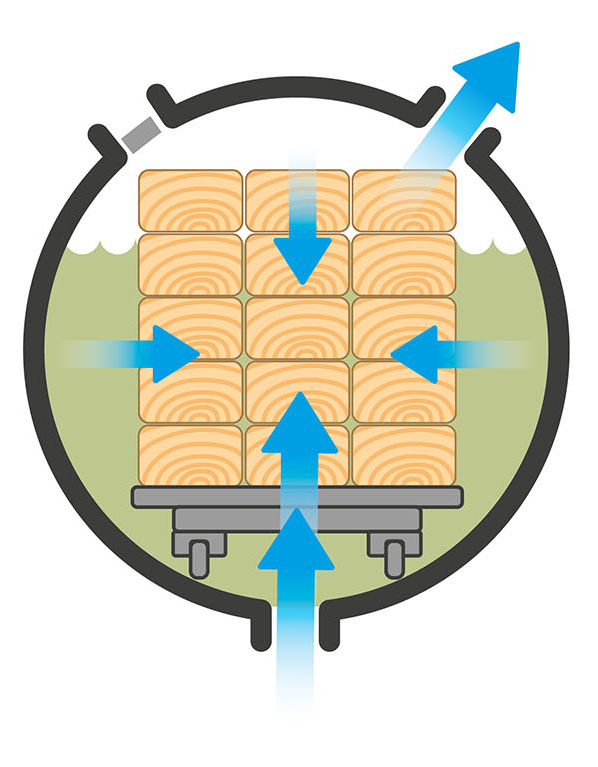

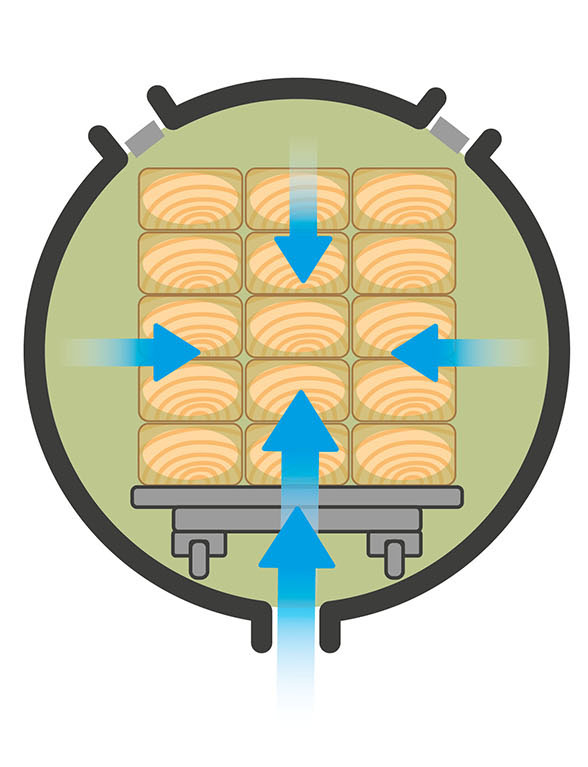

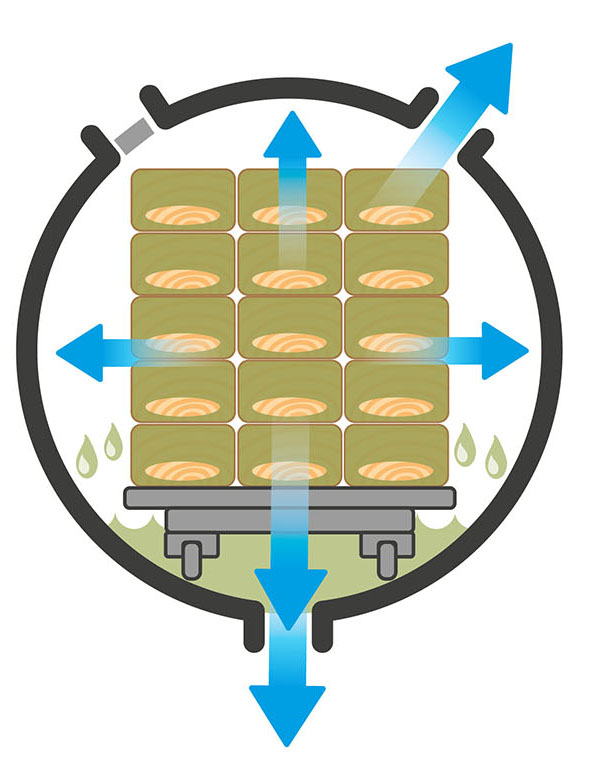

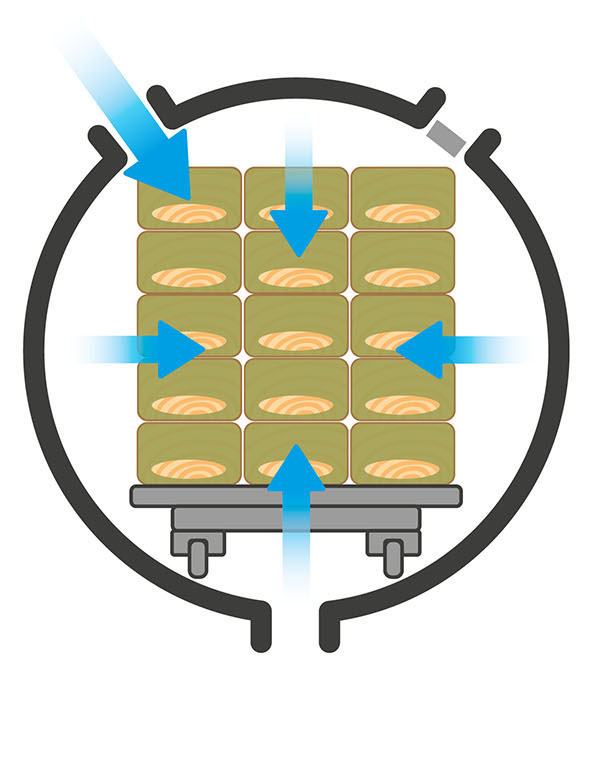

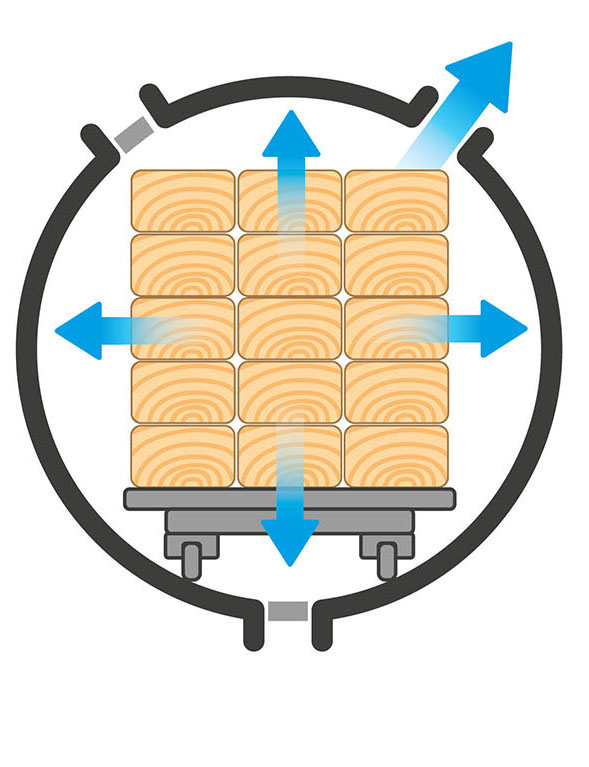

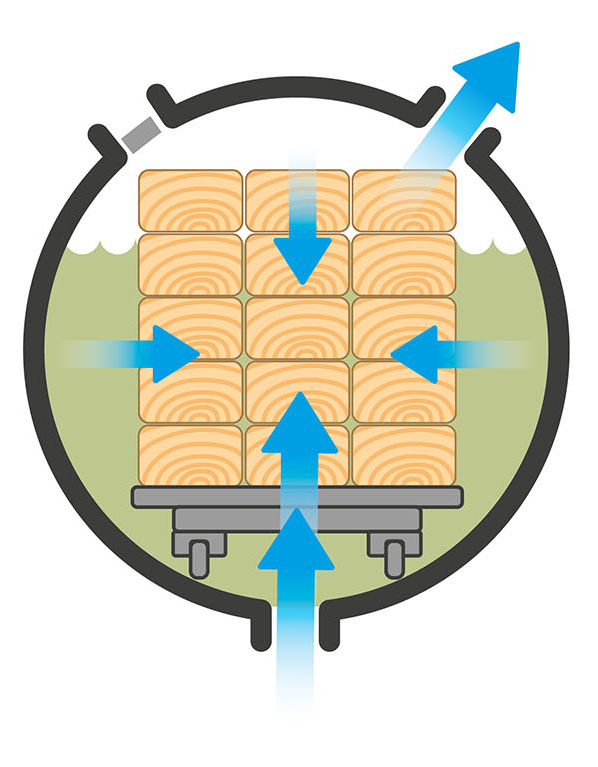

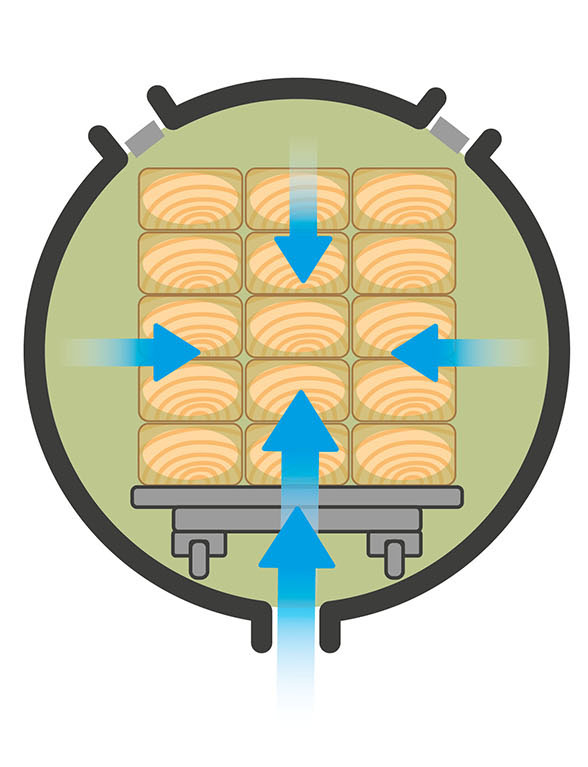

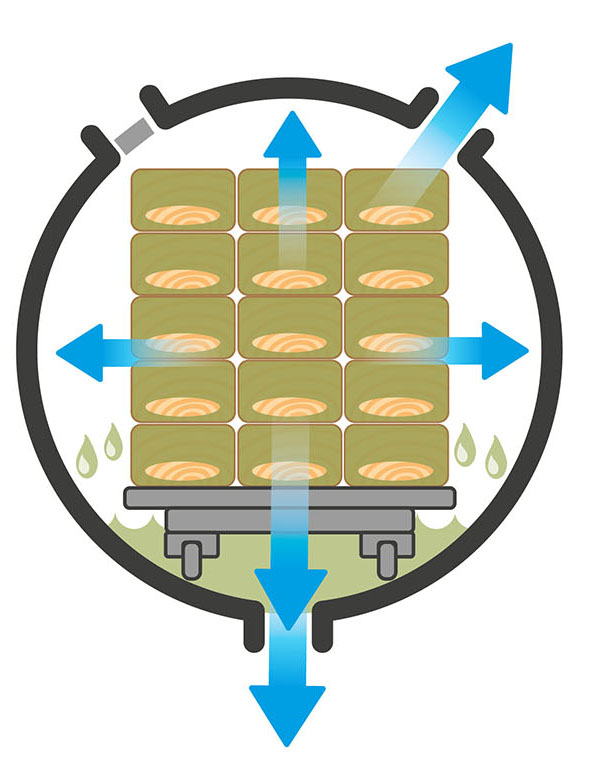

Click on the image to watch a video of a typical high pressure treatment process.

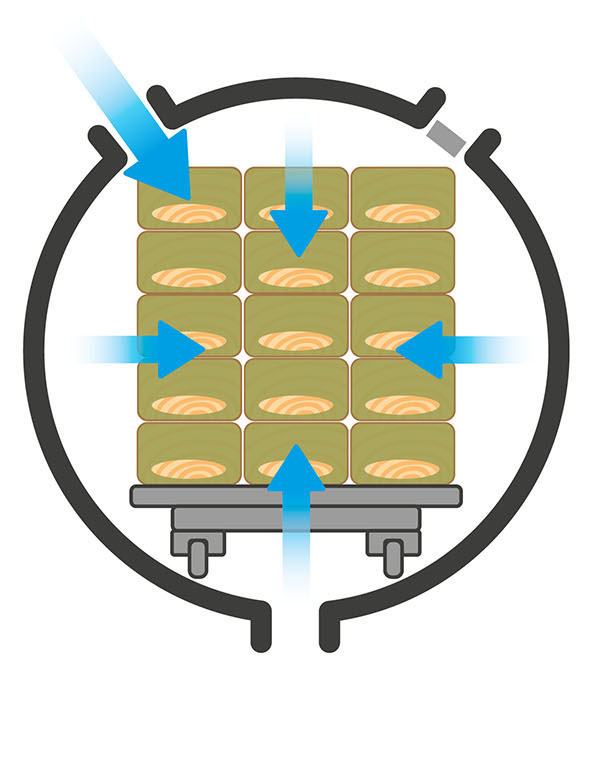

Click on the image to watch a video of a typical high pressure treatment process.